Heneways Editorial Team

2024-06-14

Reading time: 10 minutes

13 June 2024

Dear Valued Client,

RE: UNDERSTANDING CURRENT SUPPLY CHAIN DISRUPTIONS

We hope that this message finds you well.

We recognize the significant challenges you are facing due to the current supply chain disruptions. The imbalance between demand and supply of container slots, extended transit times, and rising shipping costs have created a complex environment for global trade.

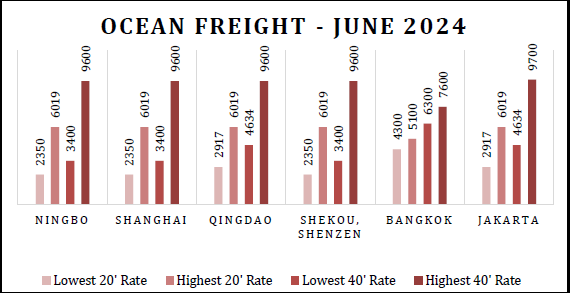

The situation is challenging, particularly for South Africa, given our extended transit times and ongoing delays. Companies transporting goods from Asia to South Africa are facing costs in the region of USD10,000 for an urgent full-size shipping container over the next month. This is about double the current spot rates (which I have indicated below), according to prices circulating between carriers and importers. We are acutely aware of these cost pressures and are working diligently to find solutions that minimize the impact on your business.

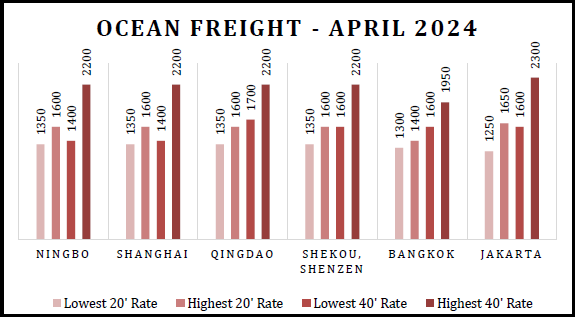

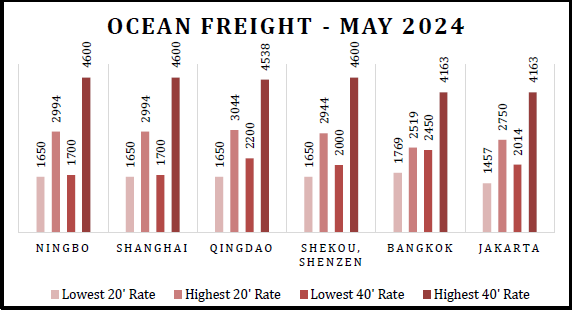

We have seen a steep increase in Freight rates from China and Far East Asia since the end of April / beginning May, since then rates have doubled. Rates continue to increase due to the factors listed below. There are no guarantees of space or equipment availability at the moment, and the bookings are constantly rolling.

Currently, MSC Diamond Tier rates of over USD9,500 per 40’GP container, is the only carrier providing us with bookings. Contract rates are not being honored by the carriers, and the bookings are being awarded to the highest bidder. There have been various blank sailings, which have aggravated the current situation.

Here is a summary of the current state of the Global Supply Chain Market:

- Rising Port Congestion: Increased activity at major ports worldwide is causing significant delays. Ports are struggling to manage the high volume of goods being shipped, leading to longer waiting times for vessels.

- Shortage of Container Equipment: There is a notable scarcity of containers, which is crucial for transporting goods. This shortage is impacted by a range of factors, including imbalances in global trade and disruptions in container manufacturing and distribution.

- Limited Vessel Space: Shipping companies are facing a shortage of available space on vessels. The high demand for shipping services, combined with operational challenges, has led to a capacity crunch, making it difficult for businesses to secure shipping slots.

- Longer Voyage Routes: Vessels have continued to sail around the Cape of Good Hope instead of through the Red Sea and the Gulf of Aden. This detour adds approximately 6,500kms to the total voyage length, resulting in longer voyage times and higher operational expenses.

- Increased Fuel Costs: The detour around the Cape of Good Hope has resulted in a 40% increase in fuel costs for carriers compared to the route through the Red Sea and the Gulf of Aden. This significant rise in operational expenses is further straining the financial resources of shipping companies.

- Disruption of Global Trade: With 30% of global container traffic passing through the Suez Canal, changing to longer routes has severely disrupted global trade. Vessels are tied up on longer journeys, leading to an estimated 15-20% reduction in available industry-wide capacity in Q2 of 2024.

- Delays and Congestion in Key Ports: Key ports, including Singapore, Ningbo, and Shanghai, are experiencing significant delays and congestion. Operational bottlenecks, vessel bunching, as well as equipment and capacity shortages, are all contributing to these delays.

- Impact on Supply Chains and Inventory Management: Delays and longer transit times are affecting supply chains, inventory management, and production schedules globally. Businesses are struggling to maintain inventory levels and keep production on track, leading to potential stockouts and production halts.

- Higher Operational Costs: The combination of longer shipping times, increased fuel costs, and operational bottlenecks is leading to higher operational costs for businesses across the industry. This is putting additional financial strain on companies already dealing with supply chain disruptions.

- Negative Impact on Imports: These issues are collectively hampering the flow of goods into countries, causing delays and increased costs for importers. The supply chain disruptions are affecting various industries, leading to shortages of products and materials.

In summary, the current high demand for container slots, extended transit times, and rising costs are posing significant challenges to global supply chains. We anticipate that the disruptions will continue into the second half of 2024.

We appreciate your patience and understanding as we work through these unprecedented times. Please note that whilst we are doing our utmost to mitigate these delays, some aspects may remain beyond our immediate control.

Rest assured, our resolute team will always provide you with the highest level of service and support. If you have any questions or need further assistance, please do not hesitate to reach out to us.

Thank you for your continued trust and support.

Kind regards,

Claudia Swanepoel

Head of Customer Services